EE Proto utilizes 3D Printing to enable companies, inventors, makers, engineers to launch new products to market in a much easier, faster and affordable way.

Additive manufacturing is based on a computer aided design file and a specialised hardware to deposit material layer by layer, in a precise geometric shapes. This approach is contrary to other machining methods based on material subtraction. Using additive manufacturing complex objects can be obtained , while the same object needs different parts and different machining with the classic approach.

The key benefit of 3D Printing is cost saving! We recommend 3D Printing before expensive machining or for product presentation.

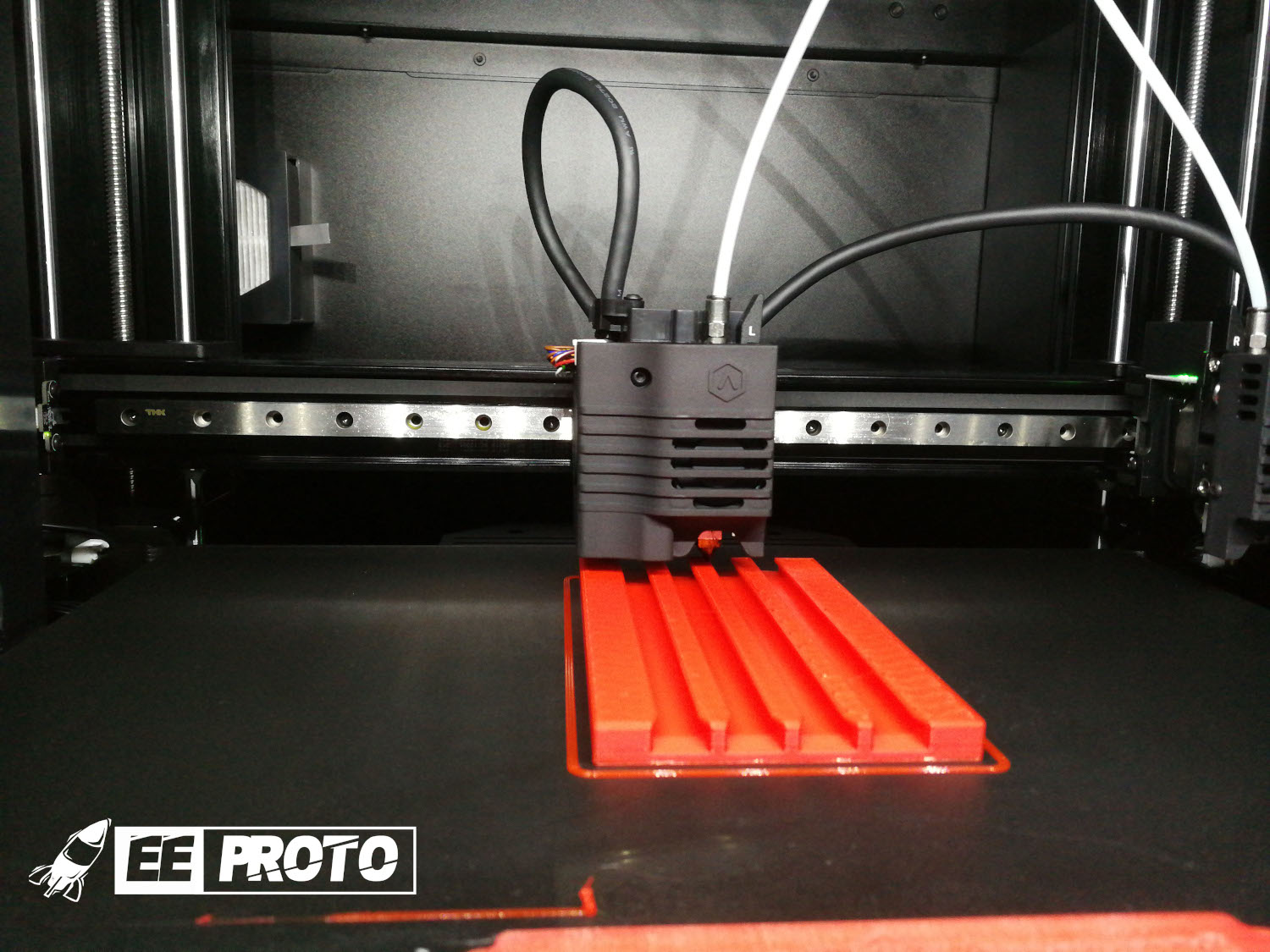

Currently we use high-end printers based on Fused Deposition Modeling (FDM) technology. FDM is an additive manufacturing process that belongs to the extrusion family. The final object is built by deposition of melted thermoplastic polymer layer by layer. We are using FMD technology because it is the best known technology and various materials, colors and textures are available for affordable price.

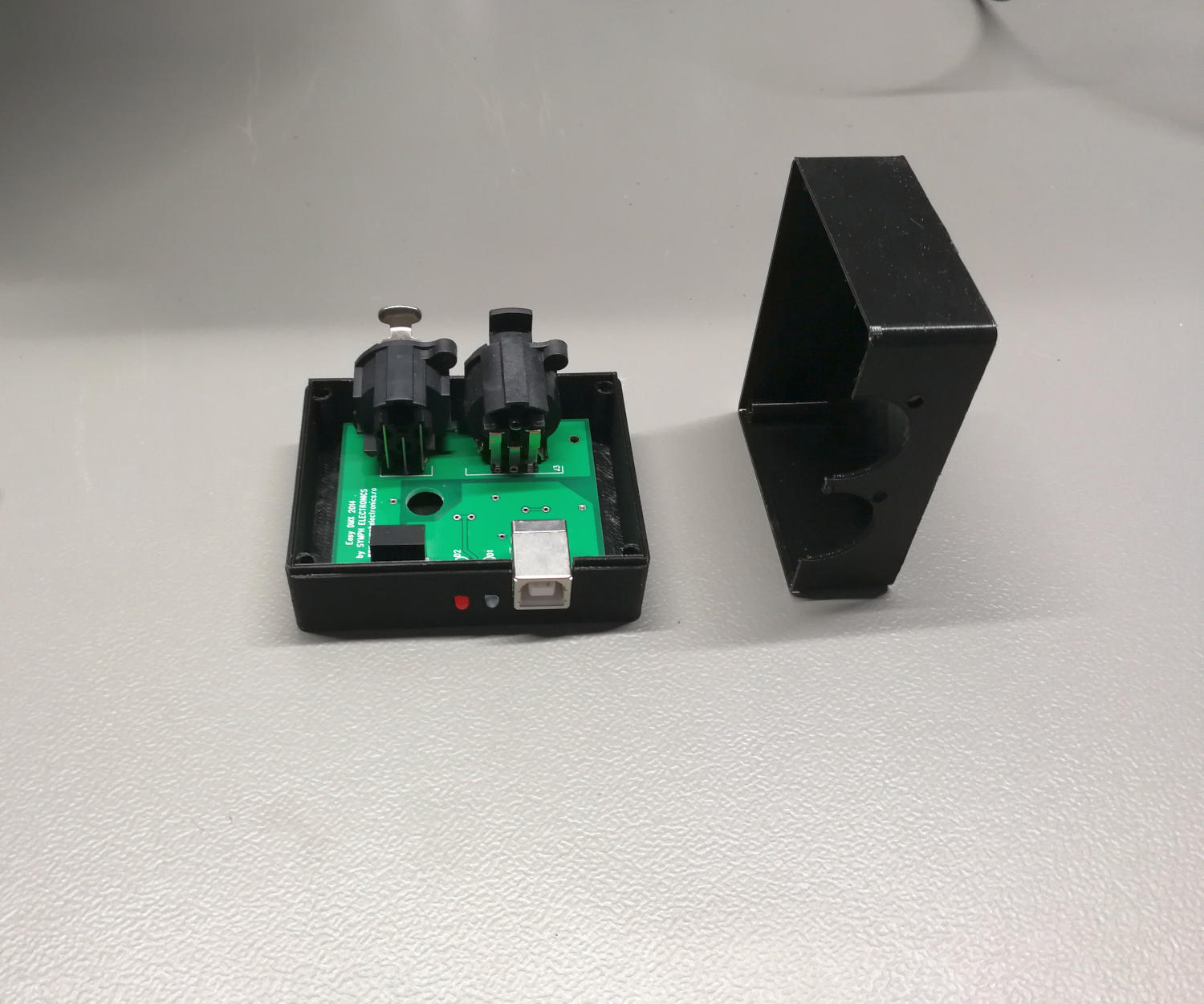

We can print your objects with standard materials like PLA, ABS, PET or industrial materials like ASA, ESD-ABS, Carbon Filled, antimicrobial filaments, etc . In case of small dimensional parts we offer alcohol vapour post processing.

Our max build volume is : 330x240x240 mm.

Based on the model we chose the best sized nozzle from 0.2 - 0.8mm (horizontal resolution) and layer height from 80-400 microns (vertical resolution).

Our printers are based on Independent Dual Extruder (IDEX) technology enabling us to print dual colored objects, print support for complicated objects or double the productivity.